waste management facilities

Coparm designs manufactures and installs waste management facilities and specific treatments, transport and sorting plants for recyclable materials such as paper, waste collection, multi-material, and industrial waste similar. The success of the treatment of waste fractions is mainly linked to the selection that is made to the origin, greatly improving the recovery rate.

Coparm offers solutions starting from basic systems for manual or mechanical and more complex plants involving specific machinery and equipment more and more ‘sophisticated to get results in full compliance with current regulations regarding waste disposal.

Coparm can offer a mixed recycling service to include cardboard, paper, newspapers, plastic films and bottles and steel and aluminium cans, which can all be put into one bin. There’s no need to separate them, so you can increase your recycling rate simply and more effectively. It not only saves time and hassle, but reduces costs by avoiding disposal to landfill.

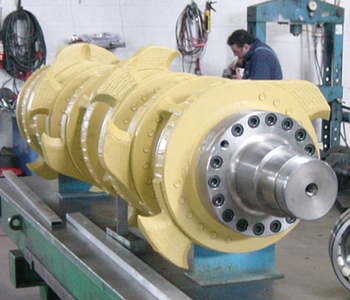

Systems for the treatment of W.E.E.E.

Electronic waste is a problem that Coparm can transform into an opportunity for any clients that have to treat from 500 kg/h to 6000 kg/h.

An in-depth knowledge of the destination markets of materials resulting from the recycling process allows us to assist and advise clients on the process most suited to their activity, on the basis of the volumes and the quality of the incoming material.

W.E.E.E. essentially encompasses a vast range of waste that is treated with systems studied in detail according to their features (large presence of metal in the “white” W.E.E.E. as opposed to electronic chips in the W.E.E.E. from offices, etc.).

SOLUTION FOR UP TO 1500/3000 KG/H OF WHITE AND BROWN W.E.E.E.

After an initial phase of manually separating cables, batteries, toner and other easily retrieved elements, the appliances are sent to the first shredding/opening phase. Once again, the outgoing material undergoes a manual search to remove cables, glass, batteries, electronic cards, transformers, electric motors, etc. The remaining material continues along the belt to the shredder, which reduces the material to pieces ideal for the following magnetic, inductive and densimetric separation systems.

SOLUTION FOR 4000 TO 8000 KG/H FOR WHITE W.E.E.E.

Coparm is able to offer a compact solution for the treatment of white W.E.E.E. that permits the material to be developed and used in a single step and with minor investment, or a more articulated solution to obtain the maximum quality of end materials for an even greater yield.

AVERAGE RETURNS FROM A TON OF INPUT MATERIAL

40% plastic

30% steel

10% electronic circuit boards

7% aluminium

6% copper

2% cables

5% material to be disposed in a landfill

Material recovery facility

Municipal Solid Waste Recycling

Single Stream Recycling

Waste to Energy

Construction & Demolition Recycling

e-Waste Recycling Equipment

Municipal Solid Waste Recycling

Coparm is leading the industry in Municipal Solid Waste (MSW) Recycling. With much of the industry heading towards MSW material mixes, we have stayed ahead of the technological curve to provide the most advanced systems and equipment to get the job done.

Our experienced design team will work directly with you to customize your MSW processing system to suit your particular needs. Every community has its own unique material mix, and our engineers will find the best possible solution to recover valuable commodities.

Coparm’s technology is field-proven to divert waste from entering landfills. Our MSW recycling systems are used in combination to recover valuable commodities, divert waste from landfills, and as a front-end separation system combined with energy conversions such as Refuse Derived Fuel (RDF) and others. Whatever your goals are, we provide you with the right and best solution.

Increased Diversion Rates, Increased Revenue Streams

Single Stream Recycling

Coparm was one of the first equipment manufacturers to engineer and manufacture sorting equipment for single stream recycling systems. Coparm has been recognized for decades as the leader in single stream recycling technology, setting the bar on performance and efficiency standards across the industry.

Coparm engineers and manufactures superior sorting equipment and systems to automatically separate your commingled recyclables into the most marketable end-products. We provide complex fully-automated systems, as well as simple commingled sort lines.

Our experienced design team works closely with you to customize your single or dual stream recycling system to suit your particular needs. Our material recovery facility technology enables you to achieve accurate separation and minimal residue with reduced personnel maintenance costs.

We are devoted to ensuring you are prepared for success, and will work closely with you each step of the way along with offering continuous excellent after-sale support.

Single Stream Recycling Equipment

Dual Stream Recycling Equipment

Commercial and Industrial

Single Stream Recycling Equipment

Coparm’s single stream recycling equipment is known industry-wide to be the most durable and reliable option on the market. Our advanced and patented disc screen technology is designed to cut maintenance costs, increase automation, and maximize up time as well as your end-product marketability.

Coparm’s Single Stream Systems separate glass, plastic, aluminum, steel and fiber (OCC, ONP and mixed paper) with the highest efficiency in the industry, separating all commodities into a clean and profitable material stream.

Dual Stream Recycling Equipment

Dual Stream Recycling is where Coparm’s history of sorting commingles materials began. Many decades ago, Coparm realized there was a need growing for curbside collection recycling, and turned their design and engineer efforts towards commingled container sorting. Coparm engineered, manufactured and installed the industries first commingled container and fiber sort lines

Coparm Manufacturing can design a Commercial and Industrial (C&I) Waste Processing System based on the material composition you are collecting. No matter from what type of business your material stream originates, whether it is factories, offices, restaurants, institutions, or retail shops, our experienced design team will work with you to interpret the best system layout and equipment to recover valuable commodities. The C&I material generally consists of office product packaging, production wastes and can include fiber, cardboard (OCC), wood, metals, glass, textiles, containers and aggregates.

Ultra-Efficient Equipment, Maximum throughput

Coparm Manufacturing can help you recover recyclable commodities in the recycling stream which will increase your diversion rates and will give you a reliable revenue stream. Coparm can design a system for you to capture these materials by combining a series of trommels, screens, conveyors and other separating equipment. See all of our recycling sorting equipment here.

Waste to Energy

There are a number of new and emerging waste to energy technologies that produce refuse-derived fuel and energy from municipal solid waste. Our task is to recover valuable commodities out of the waste stream and prepare the residue for efficient conversion before entering the waste to energy system. The Coparm Group is at the forefront, providing solutions for efficient front-end separation systems for waste to energy facilities that meet even the most demanding performance objectives.

Coparm designs front-end separation process suited for any type of waste to energy facility, tailoring the front end separation to meet your specifications. Coparm provides efficient separation technology that will increase the quality of the salvaged end-products, and will ensure that the materials sent into the waste to energy system are suited to your exact requirements. We provide all of the front-end separation equipment- metering equipment, shredders, density separators, separation screens, eddy currents, ferrous-removing magnets, optical sorters, trommels, conveyors, and balers. See all of our waste to energy equipment.

Waste to Energy Equipment

Food Waste Recycling

Green Waste Recycling

Waste to Energy Systems

Waste to Energy Equipment

Coparm’s efficient front-end waste to energy equipment for fuel preparation and materials recovery can be paired with any waste converter technology. We provide the most proficient design and layout to ensure you are able to meet your business goals.

Food Waste Recycling

Food waste, any food substance that is raw or cooked, and then is discarded, has been a growing concern in the recycling and waste industry. With this also comes opportunity. According to EPA, food waste accounted for nearly 14% of all MSW generated in 2010 and is now recognized as the single largest component reaching the landfills. Food waste is often source separated; in this case we shred and remove packaging. The Coparm Group has the right equipment and solutions to turn this problem into an opportunity.

Food Waste Recovery and Recycling

We can offer a series of trommel screens with the right size specifications to separate food waste from a waste stream. We pair our trommel screens with other separation equipment such as magnetic separators if you are using anaerobic digestion or sending food waste to compost, which offers the benefits of resource recovery as well as creating an incredibly beneficial product from organic waste that would otherwise have been sent to landfill. Food waste needs to be separated early from any waste stream, whether it is at a municipal solid waste material recovery facility, composting site, or front-end waste to energy systems; see all of our recycling sorting equipment.

Green Waste Recycling

Green waste is biodegradable waste that is composed of garden or park waste, such as grass or flower cuttings and hedge trimmings, from residential and commercial sources. Green waste can be decomposed and recycled into organic matter that can be used for various applications. Some means of processing green waste are by composting, anaerobic digestion or gasification. Sometimes, green waste is mixed with other municipal solid waste and needs to be separated from the waste stream in order to be processed, Coparm Group separating equipment is the solution.

Green Waste Recovery and Recycling

The Coparm Group can provide efficient and effective durable equipment to separate green waste from the material stream. In the cases where the green waste is source separated, we provide the bulk material handling equipment and shredders while removing metals that may be in the stream. See our trommels and other green waste recycling equipment.

Waste to Energy Systems

There are many different waste to energy systems and processes that create energy from waste streams. Coparm will compliment your process with the most reliable and efficient front end systems.

Mechanical Biological Treatment (MBT): MBT plants are designed to process mixed household, commercial and industrial waste. The process combines a front-end sorting facility with a form of biological treatment such as composting or anaerobic digestion.

Refuse-Derived Fuel (RDF): RDF is produced by shredding and dehydrating municipal solid waste. Glass and metals as well as other non-combustible materials are removed by mechanical separation leaving only the combustible materials such as plastics and biodegradable waste. RDF is often used in cement kilns and gasifiers.

Pyrolisys: Pyrolisys is the thermo-chemical decomposition of organic materials at high temperatures without the use of oxygen. It is used mainly to produce charcoal, methanol, gasoline, biofuel and other chemicals, and to turn waste into safely disposable substances.

Anaerobic digestion: Anaerobic digestion is a process in which microorganisms break down biodegradable material without the use of oxygen; it is good to use on material with high moisture content. Anaerobic digestion is used to manage waste and produce energy. The end result, after many series of digestion treatments, is methane and carbon dioxide.

Gasification: Gasification is a process that converts organic materials into carbon monoxide and hydrogen, the resultant gas is a source of syngas, renewable energy when it is not derived from fossil fuels. That organic material reacts at high temperatures with a controlled amount of oxygen and without the use of combustion. Some types of gasification are plasma arc waste disposal and fluid bed gasification.

Biodrying: Biodrying is the process where biodegradable material is heated rapidly throughout the initial stages of composting, which removes moisture from the waste and reduces it in size and weight. It is a fairly quick process that uses minimal electricity and aerobic bacteria often in mechanical biological treatment facilities. It can be used in the refuse derived fuel process or applied to mechanical biological treatment plants.

Construction & Demolition Recycling

C&D Recycling Equipment

e-Waste Recycling Equipment

E-Waste Recycling Equipment Electronic Waste (e-Waste) consists of computers, televisions, monitors, laptops, cell phones, DVD players, etc… Electronic discard is one of the fastest growing segments of our nation’s waste, already consisting of 5% of the total waste volume. According to the Environmental Protection Agency (EPA), an estimated 30 to 40 million PCs will be ready for “end-of-life management” in each of the next few years. E-Waste has a variety of valuable metals and minerals to be recovered. There are very hazardous materials within electronic waste and must be disposed of properly.

e-Waste recycling is a challenge due to its inhomogeneous nature. There are a variety of particle size distribution, shapes and materials with an increased pressure for recovery. The Coparm Group has risen to the occasion, leading the industry with innovative technology and features to overcome challenges faced. We own our own operating electronic recycling site, where we get an operators perspective and are able to field-test all of our electronics recycling equipment before selling to customers, giving us a huge advantage over our competition and better enabling us to gain hands-on experience with e-waste recycling.

Construction & Demolition Recycling

With our experience and expertise in the electronics recycling realm, we offer equipment that can rise to the challenges faced, increasing recovery and maximizing your profits. The materials being recovered are largely ferrous metals, aluminum, copper, circuit boards as well as the plastics ABS, HIPS, PC and ABS-PC.