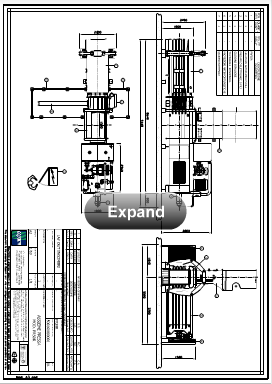

The press for waste packaging Mod. PR 50 is a sturdy machine designed especially for the packaging of liquid containers in PET and PE (CPL). In the design we considered all the issues of the specific sector with particular attention to the wear of the chambers compaction and density of the bales produced.

The machine is equipped with an hydraulic system that gives high specific pressure on treated materials, compaction chamber entirely lined with interchangeable panels of wear-resistant steel, discharge of waste packaging, special cutting blades, proportional control of channel pressure and graphic display touch screen with diagnostic functions.

The machine is also suitable for the packaging of other categories of goods such as paper, cardboard, plastic coverings. Thanks to the technical of which is equipped is also able to pack municipal waste and similar. The robustness of the structure make it suitable for the disposal of considerable amounts of waste and a duty cycle equal to other presses of our sign production of cuts higher

Coparm baler range