waste tyres recycling plant

Coparm designs manufactures and installs waste tyres recycling plant and specific treatments, transport and sorting plants for recyclable materials such as paper, waste collection, multi-material, and industrial waste similar. The success of the treatment of waste fractions is mainly linked to the selection that is made to the origin, greatly improving the recovery rate.

Coparm offers solutions starting from basic systems for manual or mechanical and more complex plants involving specific machinery and equipment more and more ‘sophisticated to get results in full compliance with current regulations regarding waste disposal.

The disposal of disused tyres is a very current topic. The three processing alternatives allow for different solutions: The first stage allows to obtain a reduction in size (tyre crumb) with the purpose of reducing the volumes in order to facilitate warehousing or to be used for energy production as an alternative combustible.

Tyre treatment plants

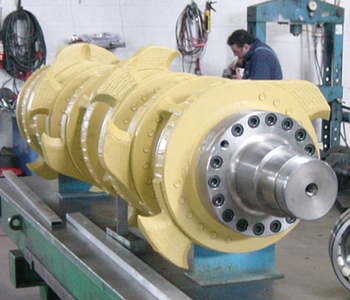

The plants offered by Coparm for the treatment of tyres enable greater flexibility of use as they are capable of treating any type of tyre, reducing them to granules.

Our plants start from the bead breaking machines, a process through which the steel wire ring inside the tyre (bead) is removed, proceeding then to the shears that cut the tyre into pieces, which are then shredded. The pieces of rubber produced from the shredder are sent, along a conveyor belt, to the next process: the granulation. The product is reduced to extremely fine granules in the granulator.

Furthermore, Coparm plants are equipped with pulverisers, micronisers, conveyor belts, augers, vibrating screens, vibrating conveyers, aspiration plants and granule moulding machines, all expertly produced in turnkey solutions that can treat from 1000 to 10,000 kg/h.

SOLUTIONS FOR VOLUME REDUCTION OR “TYRE CRUMB”

On one hand Coparm can provide solutions for the simple reduction of the volume of tyres, and plants for the production of 50x50mm “tyre crumb” pieces on the other hand. This type of plant can be installed on a semi-trailer and conveniently moved to the locations where the tyres are stored. Coparm has devised a cutting system to apply to the WD200 version of the Thanit shredder that can produce up to 6 ton/h of tyres shredded in 100mm pieces. We are particularly proud of this system as it represents the best solution in terms of hourly production for the treatment of tyres and their preparation for thermo-demolition.

SOLUTIONS FOR 20 MM CHIPS

Coparm is the exclusive holder in Italy of the international patent that enables it to produce chips from entire car tyres or pre-shredded lorry tyres, deferrized to 99.9%, with the best power/production rapport that can be found on the market (110kw for 1500 kg of material). The system is based on slow shredding with special blades. In addition to low energy consumption, the advantages include limited noise from the system (79dBA, normally when traditional technology is applied the machines used in this process must be insulated for sound) and the absence of cooling systems for the cutting tools normally provided in the machines used in this type of operation. This operation can also be used to prepare the material for the following granulation phases.

SOLUTIONS FOR GRANULES AND POWDER

Coparm can provide solutions to produce varying sizes of material from 5mm to 500 micron. The grain size curves can be suited to the most diverse requests. The particular separation systems devised by the Coparm technicians means that the granule is almost exempt of natural fibre.

STEEL: FROM PROBLEM TO OPPORTUNITY

Coparm has devised solutions and systems for a profitable and useful application of this material, usually destined to become scrap or is difficult to reuse. Making the most of steel is as important as obtaining a quality granule.