refrigerator recycling plant

Coparm designs manufactures and installs refrigerator recycling plant and specific treatments, transport and sorting plants for recyclable materials such as paper, waste collection, multi-material, and industrial waste similar. The success of the treatment of waste fractions is mainly linked to the selection that is made to the origin, greatly improving the recovery rate.

Coparm offers solutions starting from basic systems for manual or mechanical and more complex plants involving specific machinery and equipment more and more ‘sophisticated to get results in full compliance with current regulations regarding waste disposal.

The plants developed, designed and built by Coparm allow for the total recovery zero environmental impact recovery of refrigerators: air flow control, control of dust resulting from grinding, soundproofing and noise components and the total recovery of hazardous gases.

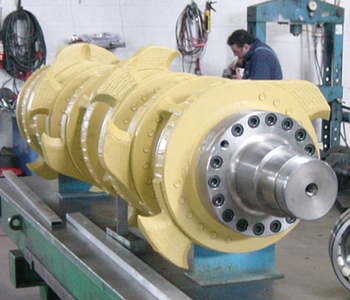

Systems for the treatment of refrigerators

SOLUTIONS OF 40 PC/H

Beginning with the entire fridge, the individual materials, such as iron, plastic, aluminium, copper, polyurethane and glass, are selected, around 90% of material, before the recycling starts.

The aspiration of gas used in the refrigeration circuits completes the recovery process and storing the gas in a cryogenic plant guarantees that no noxious emissions are dispersed into the atmosphere. This plant grants a considerable reduction in operational costs as it is designed to treat 40 pieces per hour, and is completely automated. In fact, there is no longer any need for two or three operators during the shredding phase.

AN INNOVATIVE DESIGN

The Coparm refrigerator treatment system is the result of a cutting-edge design that uses exclusive technologies. Its special features include:

safe treatment of fridges with CFC and Pentano

positive environmental repercussions (intake system and air neutralisation ensure zero emissions into the atmosphere)

its capacity to supply excellent output.

MAXIMUM SIZE OF A TREATABLE REFRIGERATOR

length 1050mm

depth 950 mm

height 2000 mm

weight 80Kg

DEGREE OF PURITY FOR SEPARATED FRACTIONS

95% in volume: polyurethane foam

98% in weight: steel fractions

93% in weight: aluminium/copper fractions

96% in weight: plastic fractions